Digital Twin Manufacturing Solution Providers

AI-Powered Visual Solutions Driving Business Growth

0%

Conversion lift

with seamless integration of our AI-driven headless checkout solution tailored for your front or back end.

Business Approaches

Discovery & Strategy

Start by reviewing the factory’s production systems, equipment flow, and efficiency targets, then work from ground up to identify weak points. Define them as clear action steps which are measurable and connect directly to long-term manufacturing goals. Ensure the platform not only addresses today’s process challenges, but also equips factories with a direction needed for future growth.

Custom Development

With advanced factory modeling tools, we deliver flexible and adaptive digital solutions. Each application strikes a balance between accuracy and efficiency which enables operators to quickly test layouts and optimize resources, cut mistakes and smooth operations across the production floor.

Seamless Integration

Connected platforms and systems bridge the gap between your digital twin models and other smart factory frameworks, device networks and enterprise platforms. This results in plant management that shifts into a self-sustaining and resilient foundation that keeps performance and reliability.

Testing & Optimization

Through steady checks, every rollout is tested for accuracy and dependability. Interfaces are designed to ensure that your factory’s digital twin runs with confidence and efficiency across different platforms and environments.

Ongoing Support

Our role is not limited to the first rollout. We provide training, updates and scaling assistance as manufacturing needs change. Your digital twin grows with your factory, with steady improvement, stronger security and new features that align with changing policies and objectives.

Digital Twin Solutions for Smart Manufacturing Systems

Drive progress in production management with advanced digital twin manufacturing services. Gain real visibility, optimize factory performance and ensure smart decision making to achieve higher effectiveness, reliability, and sustainability in every process.

Platform Features that Matter

Our Expertise in Modern Manufacturing and Connected Factory Systems

Real Power System Visualization

We provide clear, detailed, interactive displays of machines, assembly lines, and supply points for managers and engineers. Accurate modeling removes uncertainty, supports quick scenario testing, and cuts costly planning errors. This enables manufacturers to make timely, well-informed decisions, resulting in greater reliability, reduced waste, and a strong foundation for sustainable production management.

Custom Rules And Workflow

Our system applies straightforward rules to handle scheduling, resource use, and safety needs. Tailored workflows help teams stay compliant, cut down on mistakes, and speed up decision-making. Tasks that once required long calculations and repeated manual steps are now carried out in a smooth, efficient, and dependable way.

Smooth Energy System Integration

Link your factory tools with existing production control, monitoring, and enterprise systems for a unified setup. This ensures that data moves easily across departments, strengthens teamwork, boosts operational reliability, and improves overall effectiveness.

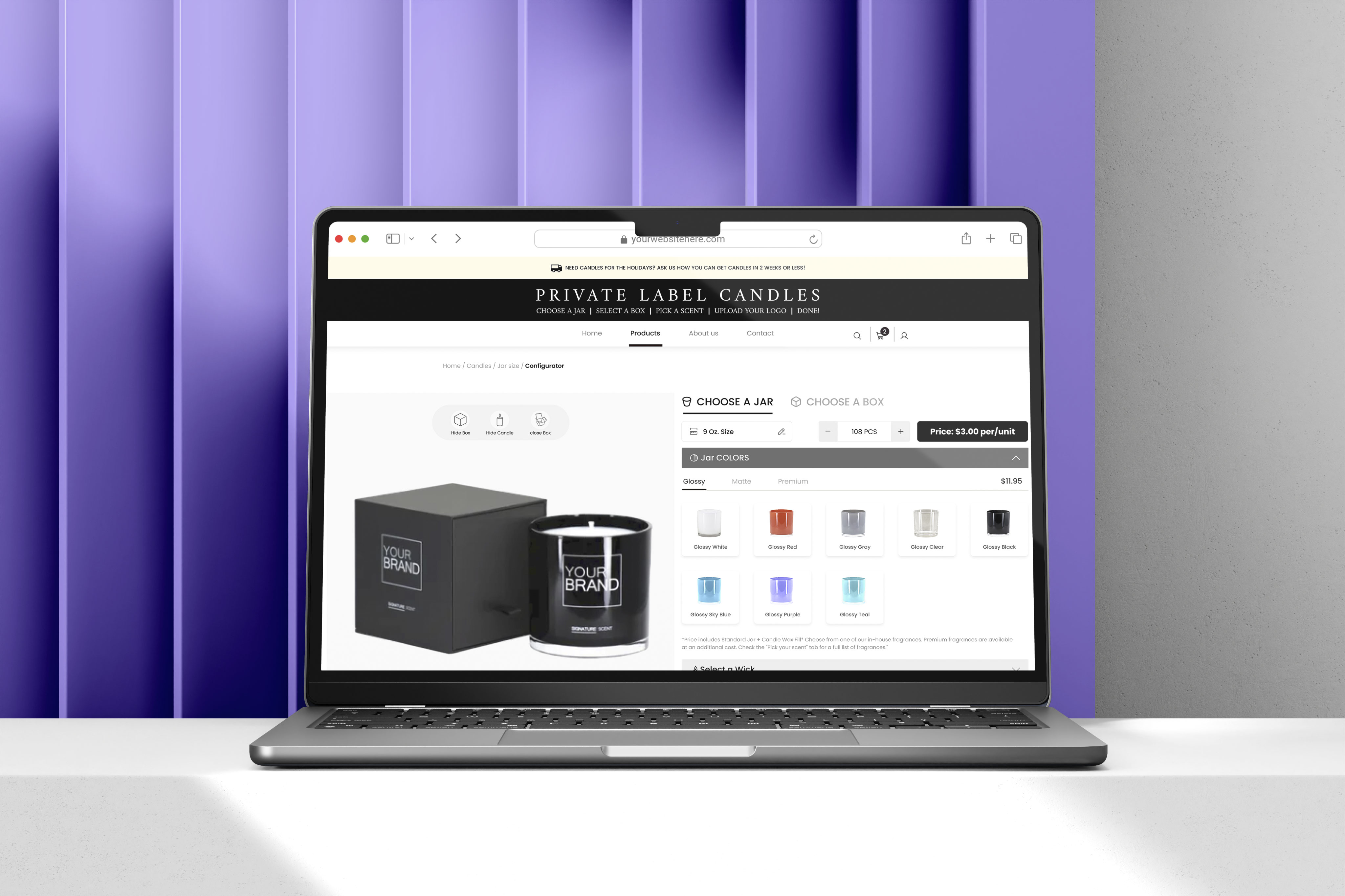

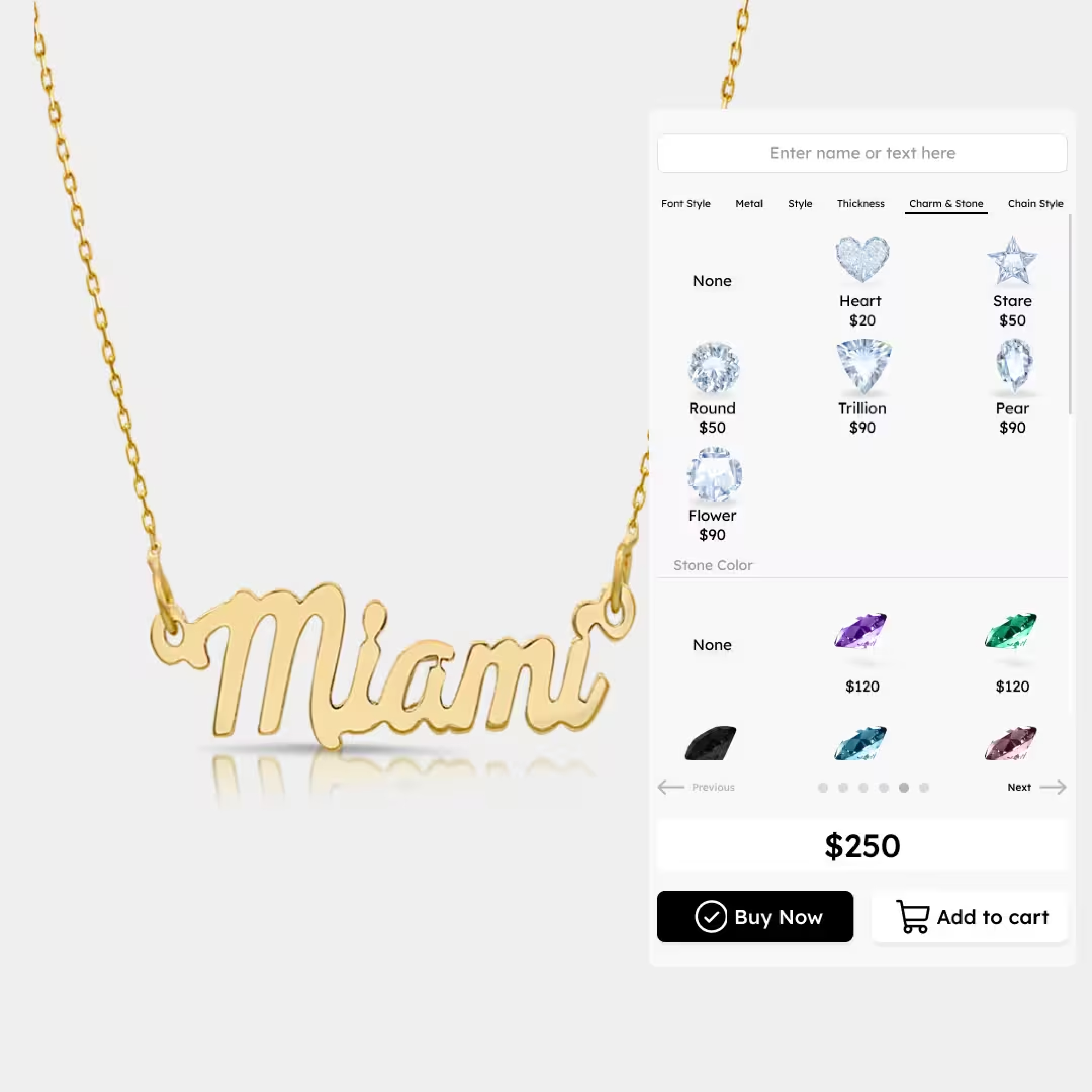

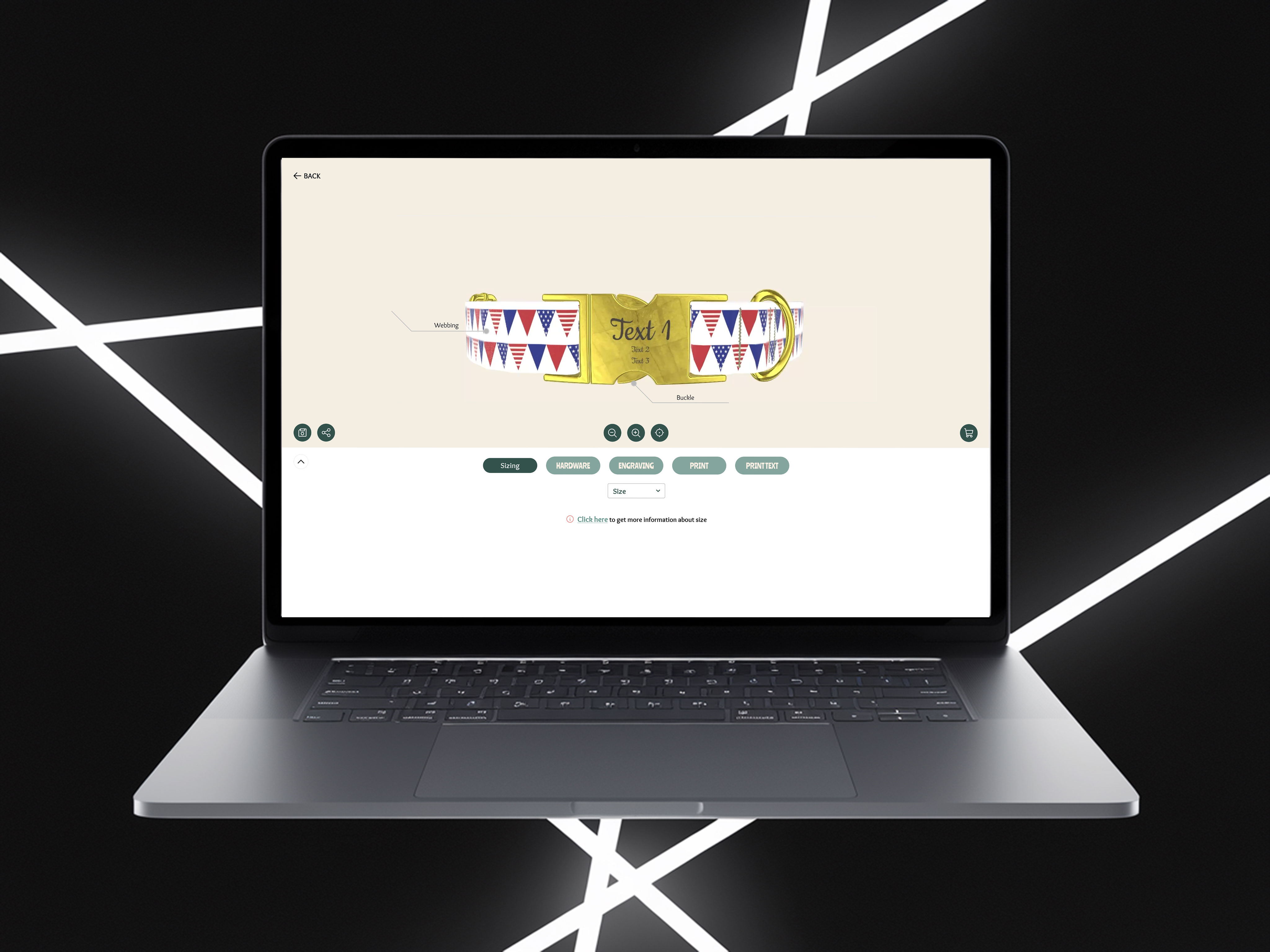

Advanced Service Combinations with 3D Product Configurators

The value of using 3D visualization into documentation is that the sequence of assembly, installation or use is much clearer than through 2D. This can reduce misunderstandings and improve the quality of documentation and user experience.

Our Available Solutions

Startup Solutions

For digital twin manufacturing focused startups, our cost estimation tool provides advisory to better prepare financially and utilize for resource allocation.

Business Solutions

For growing factories, our affordably priced detailed project estimations will help balance budgets for scaling digital twin manufacturing capacities ensuring cost effective growth, predictable investment in systems, and better planned workflows across production lines.

Enterprise Solutions

Detailed analysis for large manufacturers and corporations, combined with our customer centric approach, allows us to provide valuable insights on comprehensive factory projects, optimizing resource expenditure and controlling deployment costs for seamless functionality across various units.

Digital Twin for Smarter Manufacturing

Optimize operations with real-time insights, predictive maintenance, and virtual simulations to boost efficiency and reduce costs.

Serving our clients across the diverse industries

Explore Our Portfolio

Why Companies Choose HexaCoder?

HexaCoder’s manufacturing digital twin technology creates real-time virtual replicas of factory assets, processes, and systems. This enables continuous monitoring, predictive maintenance, and enhanced decision-making for optimized operations.

Cutting-Edge Technologies for 3D Configurator Development

We leverage the latest technologies to deliver exceptional 3D configurator solutions.

Testimonials

Your industry, our tailored solutions

We have a pulse on business trends and market developments to help you become an industry leader!